Printed Flavors

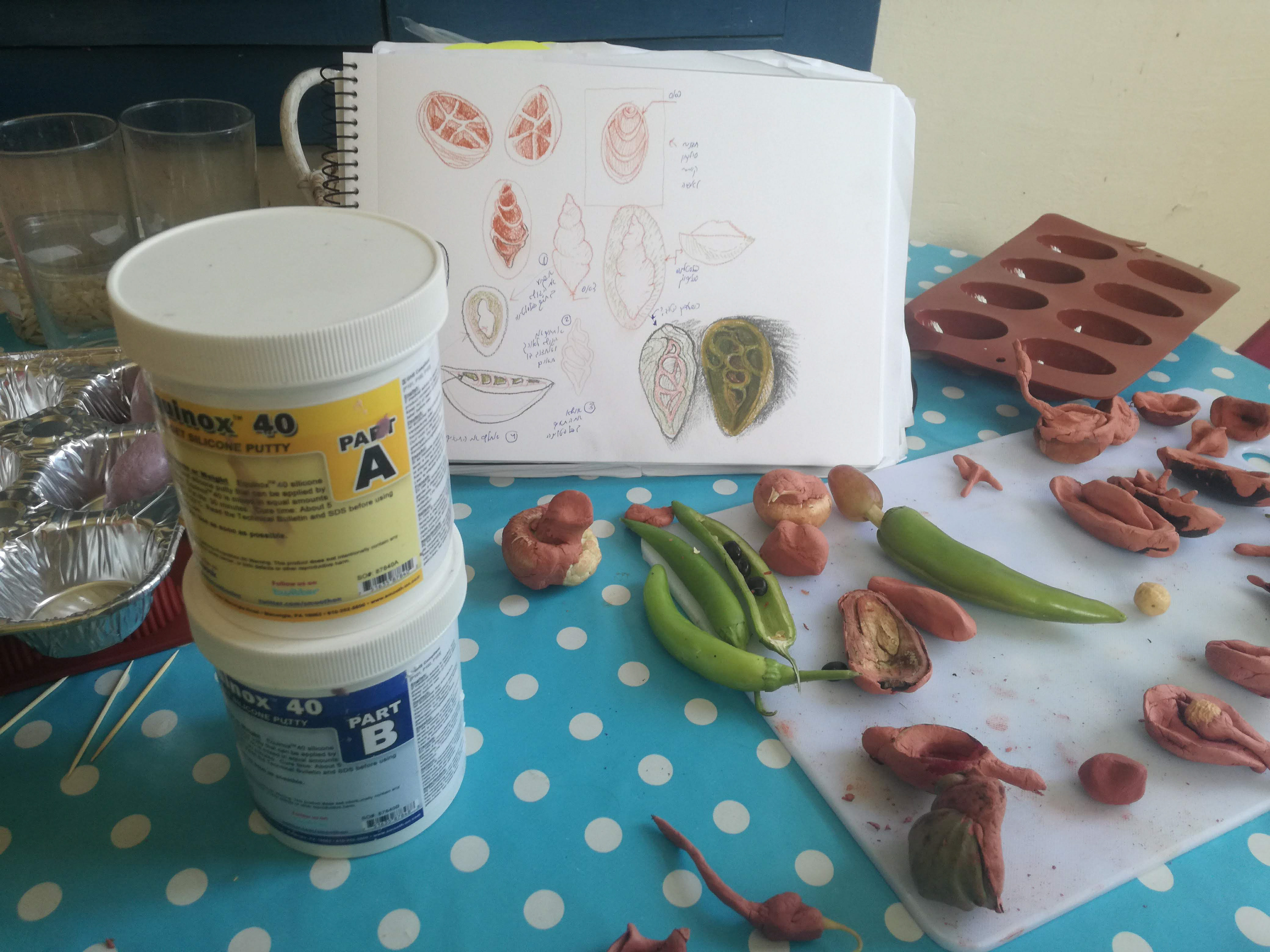

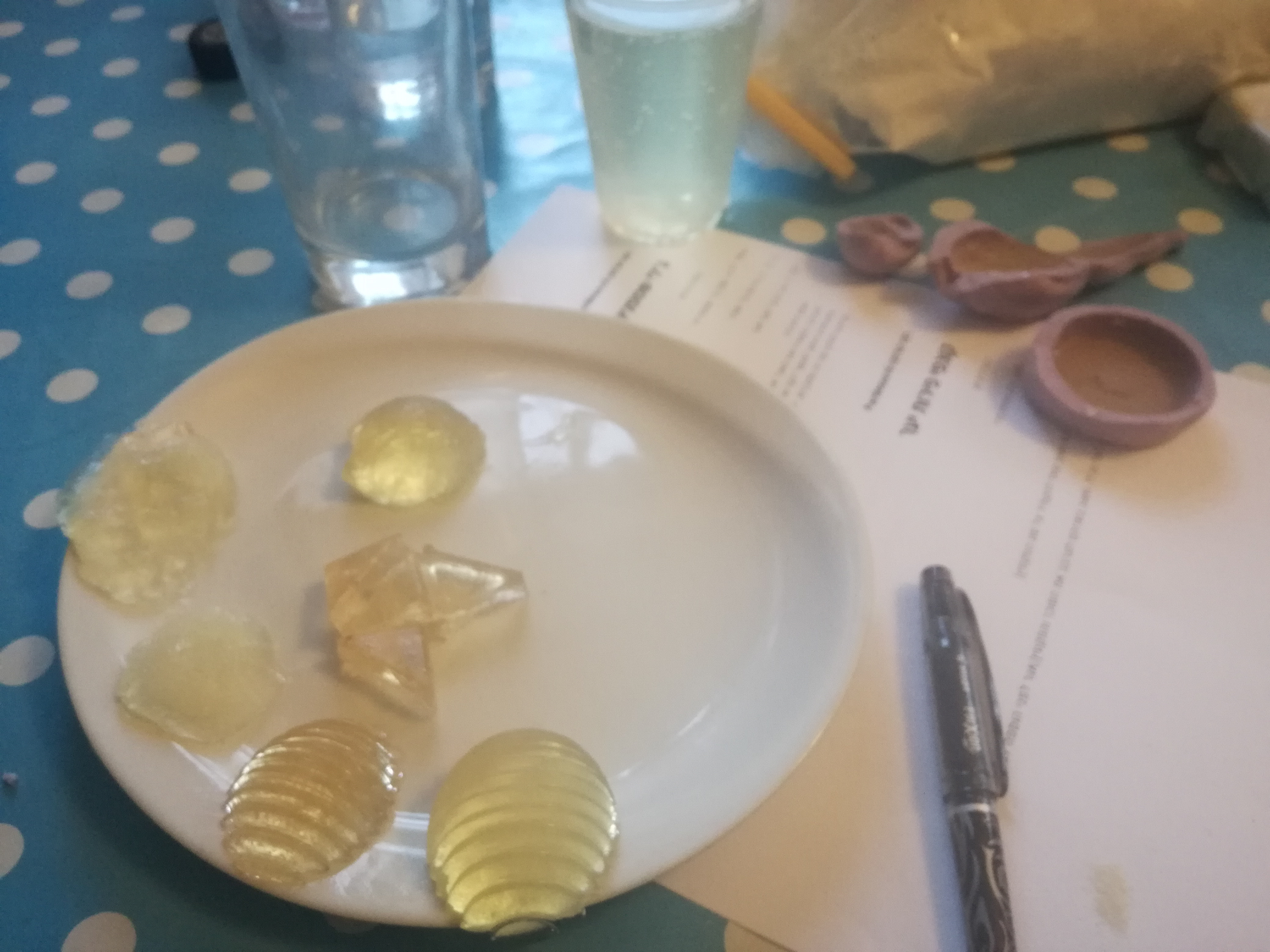

an ongoing project of printed flavors - researching the way to print 3d bite sized

in-mouth experiences based on the topographical change inflicted upon a single material. Flavor pairing of gels.

in-mouth experiences based on the topographical change inflicted upon a single material. Flavor pairing of gels.

By 2050, the world population will surpass nine billion people, meaning a higher demand for available food, water, and environmental impacts. Possible solutions for food safety issues include advancements in food processing technologies, nanotechnology, innovative food formulations such as alternative protein sources, insect flour, nutrigenomics, 3D food printing, and biomimicry.

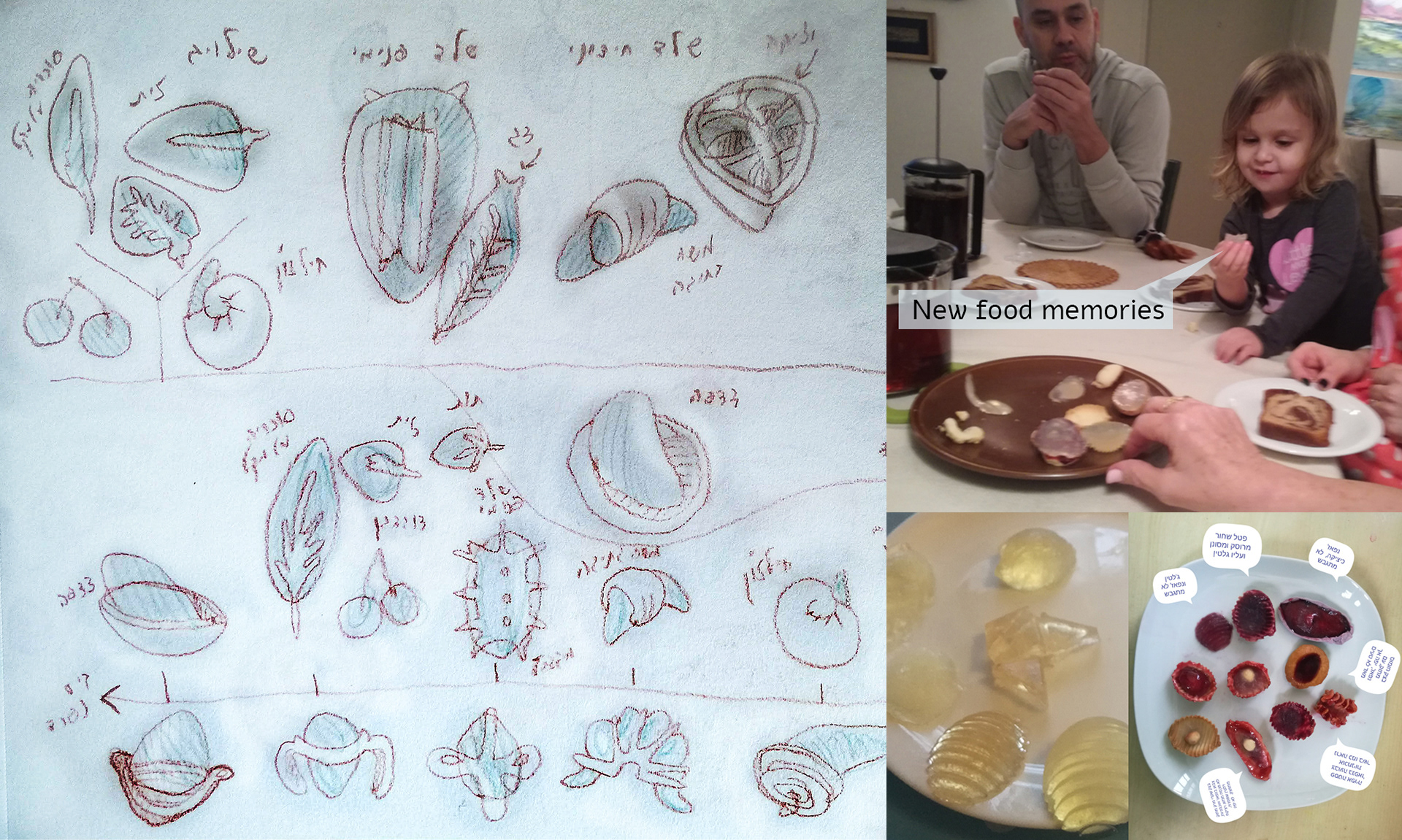

Culturally speaking we might be wiping out food production techniques and age-old traditions, flavors, and ingredients that define folks. 3d food printing relay mostly on mashed food that strips the food from its origins, textures, associations, and cultural references.

Off the shelf mashed food lacks texture. This fact is both an opening for adventure and a challenge.

Molecular cuisine had tricked the mind, playfully masking food origins since the 80’s. 3d food printing obscures the source of food with a heavy price of losing a crucial part of the sensorial experience of flavor and any culinary cultural reference that comes with it.

The experience of flavor relay not only on the five detectable tastes: sour, sweet, bitter, salty and umami but also on the smell. Note that 80% of our perceived experience relies on smell and not on taste. The mouth itself is a sensorial organ. It is called the mouthfeel: the ability of the mouth to sense texture, temperature and bite-size.

I’m posing at this moment of possible wipe out to inspect the way new food production methods can open new possibilities for self-expression and emotional rapport, in the spirit and aspiration of the new craft.